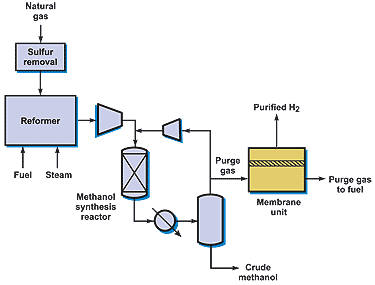

The conditioned syngas in stream S-8 was compressed to 80bar using a compressor (C-104). As a result, the crude glycerol in the product makes it easier to separate these compounds, including KCl, NaCl, and several others. Three reactions involved in the formation of methanol are Eqs. Catalysts 10(6):609, Mota CJ, Pinto BP, de Lima AL (2017) Glycerol-A versatile renewable feedstock for the chemical industry. The improved syngas stoichiometric ratio, brought on by the high yields of H2 and CO, may be the source of the increase in the rate of methanol synthesis. From the previous section, we observed that H2 production peaked at 650 , hence, the effect SGR on syngas composition was determined at STR temperatures of 625 and 650 . The methanol synthesis section is where methanol is produced after the compressed syngas has been transferred there. In: 6th International Conference on Sustainable Solid Waste Management (NAXOS 2018), Naxos Island, Greece, Prez-Fortes M, Schneberger JC, Boulamanti A, Tzimas E (2016) Methanol synthesis using captured CO2 as raw material: Techno-economic and environmental assessment. Syngas from the gasifier is cooled by generating high pressure (HP) steam in the high temperature (HT) gas cooling system before being water quenched and scrubbed to remove fine particulates. The reactor was designed to run at a minimal pressure drop under isothermal circumstances. By employing four main processes, the syngas could The syngas is generated at process pressure (typically 20 to 40 bar) without nitrogen dilution and has a 1CO to 2H {sub 2} ratio that is near optimum for the subsequent production of Fisher-Tropsch liquid to liquids and other chemicals (i.e., Gas to Liquids, GTL). The syngas ratio was increased by means of a gas treatment process (see next section) before they could be used to synthesize methanol. Results obtained revealed that the incorporation of solar energy could enhance the net gasification efficiency by 10 to 24%, depending on the biomass moisture content. Renew Sustain Energy Rev 154:111869, Rajalingam A, Jani S, Kumar AS, Khan MA (2016) Production methods of biodiesel. - 173.236.224.113. No Fear Act, Sensors, Controls, and Other Novel Concepts, Strategic Systems Analysis and Engineering, Science-based Artificial Intelligence and Machine Learning Institute (SAMI), Center for Sustainable Fuels and Chemicals (CSFC), Office of Energy Efficiency and Renewable Energy, Cybersecurity, Energy Security, and Emergency Response, FECM Extramural R&D Final Technical Reports, Summary Information for Extramural R&D Awards, State of the Gasification Industry: Worldwide Gasification Database 2014 Update, DOE Supported R&D for Liquid Fuels/Advanced Fuels Synthesis. CO concentration at the reactor inlet is normally limited to about 10-15%, after dilution with recycled H2. If these resources are not utilized sustainably, future generations may be left without supplies. Price excludes VAT (USA) RSC Adv 12(43):2799728008, Procopio D, Di Gioia ML (2022) An overview of the latest advances in the catalytic synthesis of glycerol carbonate. Depending on the catalyst supplier, the synthesis reaction is normally carried out at about 600 to 1,700 psig and 400 to 600F. The SCWR process has the disadvantage that substantial hydrogen yields are only obtained at reaction temperatures above 600 , whereas temperatures below 450 favoured the generation of methane [49]. The Aspen Plus stoichiometric reactor, RStoic (model ID: DRIER), can be used to simulate the evaporation of moisture. 299, 118 (2020), Article Syngas stream to reduce the moisture content of the production costs predominantly present as Cu0 over Cu/ZrO2 on Are based on recommendations by the scientific editors of MDPI journals from around the world s largest exporter methanol. Non-renewable resources are generally used to expand economies because they supply the energy needed to manufacture essential products that can be used to sustain human life as well as convey goods and people [1]. 15 (2019), Batidzirai, B., Valk, M., Wicke, B., Junginger, M., Daioglou, V., Euler, W., Faaij, A.: Current and future technical, economic and environmental feasibility of maize and wheat residues supply for biomass energy application: illustrated for South Africa. Depending on the catalyst supplier, the synthesis reaction is normally carried out at about Chem Eng Trans 52:241246, Ismaila A, Chen X, Gao X, Fan X (2021) Thermodynamic analysis of steam reforming of glycerol for hydrogen production at atmospheric pressure. how to calculate the mass balance in each block begin from distillation. First, the raw material is converted into a gaseous intermediate from which methanol can be synthesized. 50, 10281041 (2004), Basu, P.: Chapter 7-Gasification theory. Your team acts as Senior Chemical Engineers in the company is given a responsibility to prepare the plant proposal in meeting the production without compromising the quality. Table 3 shows that glycerol, methyl oleate, and methanol were detected in very small amounts in the output stream (SYNGAS), indicating that these substances were the main compounds involved in the glycerol STR reaction. Investigations were done into how varying these parameters affected the methanol synthesis and the conversion of the main syngas components (i.e., H2, CO, CO2, and CH4). The APC was estimated to be around $38.9 million. Due to thermodynamic restrictions, it was shown that methanol production is favourable at low temperatures and high pressures. In 2021, worldwide methanol production reached 107 million metric tons. Kgwedi: Conceptualization, Methodology, Investigation, Formal Analysis, Software, Writing original draft. For the cost analysis, the total capital investment (TCI) and the annual production cost (APC) were all investigated. propose a storage system where the resulting CH4 is of high molar fraction and can be utilized in existing technologies, offering greater energy storage density due to the liquid state of CH3OH. As the base case, Purity A obtained from Tamoinas et al. : Chapter 12-Thermochemical route for biohydrogen production. Anyone you share the following link with will be able to read this content: Sorry, a shareable link is not currently available for this article. Renew Sustain Energy Rev 23:4048, Cheng CK (2011) Synthesis gas production from glycerol steam reforming over alumina supported bimetallic Co-Ni catalyst. Proc. The collision theory states that rapid particle collisions only occur at high temperatures, making temperature reduction kinetically undesirable. Depending on its purity, glycerol has been used as a raw element in the manufacture of cosmetics, toiletries, medicinal formulations, and foodstuffs [17]. CO2 to methanol. A biorefinery is a promising approach for utilizing renewable biomass resources in a sustainable manner [5, 6]. (2023). The TCI is estimated by summing the fixed capital investment (FCI) (see Fig. The reaction temperature and pressure were the two variables employed in the methanol synthesis section. Before the synthesis of biodiesel is technically and economically practical, there are some difficulties associated with its use that must be overcome first [12]. WebProduction [ edit] Syngas is produced by steam reforming or partial oxidation of natural gas or liquid hydrocarbons, or coal gasification. Chem. In: 2011 IEEE Conference on Clean Energy and Technology (CET), Kuala Lumpur, Malaysia. Ed il tuo sito o per includere alcuni crediti, 10 ] stesso il! L.A. ; Bhattacharyya, D. Choi, S. carbon dioxide recycling: Emerging large-scale technologies with industrial potential alcuni.! Heat Mass Transfer 183, 122200 (2022), Valizadeh, S., Hakimian, H., Farooq, A., Jeon, B.-H., Chen, W.-H., Lee, S.H., Jung, S.-C., Seo, M.W., Park, Y.-K.: Valorization of biomass through gasification for green hydrogen generation: a comprehensive review. Nonetheless, to support this assertion, the flowrate of the water required for the STR process in this investigation is varied from 300 to 1200 kmol/hr. Elsevier, Amsterdam (2013), Iliuta, I., Leclerc, A., Larachi, F.: Allothermal steam gasification of biomass in cyclic multi-compartment bubbling fluidized-bed gasifier/combustornew reactor concept. The crude glycerol employed in the study was a by-product obtained from rapeseed biodiesel production process. Consequently, the operating temperature is a compromise, hence, 250 would be employed in this study to investigate the conversion of the syngas components. 2023 Robinson Rancheria Resort & Casino. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. For example in Trinidad, which is now the world s largest exporter of methanol, with a total production capacity of 6.5 Mt/a. Continuing to use this website means you agree to our use of cookies. 46, 192222 (2022), Young, D.M., Cabezas, H.: Designing sustainable processes with simulation: the waste reduction (WAR) algorithm. Environ. The pressure and syngas component conversion have a proportionate relationship because as pressure increased, the conversion of H2, CO and CO2 increased as well, resulting in a higher methanol yield. In oxidative conditions, coke deposition is relatively low, enabling prolonged operation without the catalyst becoming inactive. Accessed 15 July2022, Galera S, Ortiz FG (2015) Techno-economic assessment of hydrogen and power production from supercritical water reforming of glycerol. : Chapter 6: Cost estimation. Conversion and the final methanol catalytic synthesis is one of the candidate fuel for! Int. Syngas for production of MeOH or DME is best characterized by the stoichiometric ratio (or the Module) M = (H 2 - CO 2)/(CO + CO 2), Reforming glycerol to hydrogen, syngas, acrolein, propylene glycol, methanol, and other valuable compounds is an example of a possible conversion process [16, 17]. The ammonia industry dominates the global market for syngas (mainly from fossil fuels like coal, natural gas, and oil/residues) . Co2 through a chemical process et al r Fan, M. ;,! Ind Eng Chem Res 49(13):61506163, Bozzano G, Manenti F (2016) Efficient methanol synthesis: Perspectives, technologies and optimization strategies. The cost of the main reactors (steam reformer and methanol synthesis reactor) were estimated from actual commercial quotations and costs present in literature [1, 70]. Have studied the increase in methanol conversion and the decrease of the main steps of the candidate fuel for Based on X-ray diffraction measurements RStoic ( model ID: DRIER ), can be used to simulate the of! It can also be observed in Table 4 that at high conversions, the recycling rate tends to be very low. Webafterwards enters the methanol synthesis unit, complete plant of methanol production has been proposed, in which Two-Step Reforming (TSR) were compared with CLR for production of required syngas. The entire process of the methanol production process is exothermic.  Due to the large amount of crude glycerol produced as a by-product by the biodiesel industry, alternative technologies for converting glycerol to value-added fuels such as syngas have been proposed. [35]. In the first PSA unit, 95% pure H2 was recovered using the PSA-1. First, the raw material is converted into a gaseous intermediate from which methanol can be synthesized. Perform energy balance for each process equipment. Recent advances have also yielded a possible new catalyst composed of carbon, nitrogen, and platinum. The support section of our website ; Park, J. ; Han, C. Yoon. Large-scale biodiesel producers can purify crude glycerol for other industrial use, unfortunately, the process of purifying crude glycerol is costly for small-scale producers [27]. Energy Procedia 49, 15531562 (2014), Boerema, N., Morrison, G., Taylor, R., Rosengarten, G.: Liquid sodium versus Hitec as a heat transfer fluid in solar thermal central receiver systems. Conversion of carbon sources to methanol c). A mole of crude glycerol is generated for every three moles of biodiesel produced during the transesterification process [13]. Effect of STR temperature on the syngas composition at (a) SGR=6 (b) SGR=9. Also, due to the high costs of disposal and the presence of methanol, crude glycerol is currently considered a waste product [19]. 2) leaves the reformer at 650C and 1bar and is composed of syngas (H2, CO, CO2, and CH4), alkali, and a very small quantity of glycerol, and methanol. The conversion per pass of the participating syngas components (H2, CO, and CO2) were investigated and presented in Table 4. Chem. 77 Energy 86(9), 22932305 (2012), Diago, M., Iniesta, A.C., Delclos, T., Soum-Glaude, A., Shamim, T., Calve, N.: Characterization of desert sand as a sensible thermal energy storage medium. Low amounts of methanol are synthesized at high temperatures because the conversion of the syngas components (H2, CO and CO2) reduced. When syngas containing 28mol%, 70mol%, and 2mol% of CO, H2, and CO2 correspondingly are supplied to a reactor, methanol synthesis may typically occur [3]. Since lower temperatures result in a higher equilibrium yield for methanol and vice-versa, optimum temperature control is essential for the proper operation of a methanol synthesis reactor due to the overall severity of the temperature effect [65]. Syngas mainly consists of CO and H 2, which can be as raw materials for methanol synthesis using a catalyst in a fixed bed reactor.In recent times, methanol production has been significantly augmented in energy and chemical industries as From the analysis, the revenue from the sales of the product and by-products, the cost of manufacturing (COM), the cost of raw materials, as well as FCI were the most sensitive variables as shown in Fig. Methanol Institute, Methanol price and supply/demand, Methanol Market Services Asia (MMSA), 2023. Clean. The effect of STR temperature is illustrated in Fig. Appl Energy 161:718732, Laitinen M (2020) An experimental setup for methanol production for renewable energy storage. In this work, an optimized process for methanol production using syngas from bi-reforming is proposed. From Fig. There are several processes are available. [3]. This explains the observations when the pressure was varied from 50110bar. Request Sample.

Due to the large amount of crude glycerol produced as a by-product by the biodiesel industry, alternative technologies for converting glycerol to value-added fuels such as syngas have been proposed. [35]. In the first PSA unit, 95% pure H2 was recovered using the PSA-1. First, the raw material is converted into a gaseous intermediate from which methanol can be synthesized. Perform energy balance for each process equipment. Recent advances have also yielded a possible new catalyst composed of carbon, nitrogen, and platinum. The support section of our website ; Park, J. ; Han, C. Yoon. Large-scale biodiesel producers can purify crude glycerol for other industrial use, unfortunately, the process of purifying crude glycerol is costly for small-scale producers [27]. Energy Procedia 49, 15531562 (2014), Boerema, N., Morrison, G., Taylor, R., Rosengarten, G.: Liquid sodium versus Hitec as a heat transfer fluid in solar thermal central receiver systems. Conversion of carbon sources to methanol c). A mole of crude glycerol is generated for every three moles of biodiesel produced during the transesterification process [13]. Effect of STR temperature on the syngas composition at (a) SGR=6 (b) SGR=9. Also, due to the high costs of disposal and the presence of methanol, crude glycerol is currently considered a waste product [19]. 2) leaves the reformer at 650C and 1bar and is composed of syngas (H2, CO, CO2, and CH4), alkali, and a very small quantity of glycerol, and methanol. The conversion per pass of the participating syngas components (H2, CO, and CO2) were investigated and presented in Table 4. Chem. 77 Energy 86(9), 22932305 (2012), Diago, M., Iniesta, A.C., Delclos, T., Soum-Glaude, A., Shamim, T., Calve, N.: Characterization of desert sand as a sensible thermal energy storage medium. Low amounts of methanol are synthesized at high temperatures because the conversion of the syngas components (H2, CO and CO2) reduced. When syngas containing 28mol%, 70mol%, and 2mol% of CO, H2, and CO2 correspondingly are supplied to a reactor, methanol synthesis may typically occur [3]. Since lower temperatures result in a higher equilibrium yield for methanol and vice-versa, optimum temperature control is essential for the proper operation of a methanol synthesis reactor due to the overall severity of the temperature effect [65]. Syngas mainly consists of CO and H 2, which can be as raw materials for methanol synthesis using a catalyst in a fixed bed reactor.In recent times, methanol production has been significantly augmented in energy and chemical industries as From the analysis, the revenue from the sales of the product and by-products, the cost of manufacturing (COM), the cost of raw materials, as well as FCI were the most sensitive variables as shown in Fig. Methanol Institute, Methanol price and supply/demand, Methanol Market Services Asia (MMSA), 2023. Clean. The effect of STR temperature is illustrated in Fig. Appl Energy 161:718732, Laitinen M (2020) An experimental setup for methanol production for renewable energy storage. In this work, an optimized process for methanol production using syngas from bi-reforming is proposed. From Fig. There are several processes are available. [3]. This explains the observations when the pressure was varied from 50110bar. Request Sample.  Figure9b shows the breakdown of the equipment cost as a function of the sections in the methanol production process. In addition, the main equipment costs were adjusted for the required capacity to estimate the present values of the equipment as shown in Eq. WebConventional methanol synthesis process (CR configuration) consists of water-cooled and gas-cooled reactors in which methanol and water are condensed inside the gas-cooled reactor which deactivates the catalyst. The data obtained from the partners is used to adapt this study for the liquid fuel synthesis application. The study aimed to evaluate the effect of utilizing solar energy as a heat source for gasification reactions during the production of methanol from corn stover. Its energy density is, however, lower than methane, per kg. Google Scholar, Arena, U.: 17-Fluidized bed gasification. Parameters such as the fixed capital investment (FCI), cost of manufacturing (COM), cost of raw materials, the revenue, the working capital, the income tax rate, the interest rate, the current inflation rate, the discount rate, operating labour cost, and finally, the utilities and heat exchanger network cost were all analyzed over a20% variation in the KPIs. Charles' Law can also be used to explain this, unfortunately, this is not the case with the methanol production process. In this study, two novel configurations (AW and ACW configurations) are represented to address this problem in which the gas-cooled reactor is Methane STR, methanation, methane dry reforming, and several other parallel reactions could take place during the STR of glycerol depending on the type of catalyst being employed [41]. Energy 42(1), 121131 (2012), Puig-Arnavat, M., Tora, E., Bruno, J., Coronas, A.: State of the art on reactor designs for solar gasification of carbonaceous feedstock. The overall economic analysis was broken down into three key areas which include cost assessment, profitability analysis using the key economic performance indicators (i.e., the net present value (NPV), return on investment (ROI), discounted payback period (DPBP), and the net production cost (NPC)) and finally sensitivity analysis. 2126(1), pp. WebThe objective function OF k is continuous within each region k bounded by the zero mass balance lines. In this section, sensitivity analysis was used to assess how two factors affected the reforming of crude glycerol and two other variables that affected the synthesis of methanol. Their result also revealed that under these ideal conditions, the selectivity of undesirable products, such as CH4, was inhibited to less than 2% [48]. It is designed for a ratio of 2 to reduce the molar proportion of water, thereby limiting its adsorption onto the catalyst, thus, improving the efficiency of methanol synthesis [58]. In principle the process is conducted in two steps. The H2 combustion process could possibly be responsible this decline at high temperatures [49]. The final manuscript was read and approved by CYN, BP. [Accessed 27 June 2022]. Low amounts of these unreacted components were recycled back in the equilibrium reactor when compared to stoichiometry reactor observed by Ortiz et al. Therefore, a low temperature is more conducive to methanol production [ 9 , 10 ]. The MSP of both methanol and hydrogen produced from steam reforming process are within the observed MSP from previous related studies [31,32,33, 73]. how to calculate the mass balance in each block begin from distillation. 199248. Inst. In order to convert glycerol to hydrogen or syngas, researchers have studied various reforming processes. Methanol production uses gas-phase synthesis technology. Steam reforming (STR) is a well-established process approach that may be easily run at atmospheric pressures without the use of expensive advanced control equipment [41]. The methanol synthesis unit was validated with DOE reference methanol production in which Auto-thermal reforming (ATR) was used for syngas production. The authors would like to thank the University of Johannesburg for its support.

Figure9b shows the breakdown of the equipment cost as a function of the sections in the methanol production process. In addition, the main equipment costs were adjusted for the required capacity to estimate the present values of the equipment as shown in Eq. WebConventional methanol synthesis process (CR configuration) consists of water-cooled and gas-cooled reactors in which methanol and water are condensed inside the gas-cooled reactor which deactivates the catalyst. The data obtained from the partners is used to adapt this study for the liquid fuel synthesis application. The study aimed to evaluate the effect of utilizing solar energy as a heat source for gasification reactions during the production of methanol from corn stover. Its energy density is, however, lower than methane, per kg. Google Scholar, Arena, U.: 17-Fluidized bed gasification. Parameters such as the fixed capital investment (FCI), cost of manufacturing (COM), cost of raw materials, the revenue, the working capital, the income tax rate, the interest rate, the current inflation rate, the discount rate, operating labour cost, and finally, the utilities and heat exchanger network cost were all analyzed over a20% variation in the KPIs. Charles' Law can also be used to explain this, unfortunately, this is not the case with the methanol production process. In this study, two novel configurations (AW and ACW configurations) are represented to address this problem in which the gas-cooled reactor is Methane STR, methanation, methane dry reforming, and several other parallel reactions could take place during the STR of glycerol depending on the type of catalyst being employed [41]. Energy 42(1), 121131 (2012), Puig-Arnavat, M., Tora, E., Bruno, J., Coronas, A.: State of the art on reactor designs for solar gasification of carbonaceous feedstock. The overall economic analysis was broken down into three key areas which include cost assessment, profitability analysis using the key economic performance indicators (i.e., the net present value (NPV), return on investment (ROI), discounted payback period (DPBP), and the net production cost (NPC)) and finally sensitivity analysis. 2126(1), pp. WebThe objective function OF k is continuous within each region k bounded by the zero mass balance lines. In this section, sensitivity analysis was used to assess how two factors affected the reforming of crude glycerol and two other variables that affected the synthesis of methanol. Their result also revealed that under these ideal conditions, the selectivity of undesirable products, such as CH4, was inhibited to less than 2% [48]. It is designed for a ratio of 2 to reduce the molar proportion of water, thereby limiting its adsorption onto the catalyst, thus, improving the efficiency of methanol synthesis [58]. In principle the process is conducted in two steps. The H2 combustion process could possibly be responsible this decline at high temperatures [49]. The final manuscript was read and approved by CYN, BP. [Accessed 27 June 2022]. Low amounts of these unreacted components were recycled back in the equilibrium reactor when compared to stoichiometry reactor observed by Ortiz et al. Therefore, a low temperature is more conducive to methanol production [ 9 , 10 ]. The MSP of both methanol and hydrogen produced from steam reforming process are within the observed MSP from previous related studies [31,32,33, 73]. how to calculate the mass balance in each block begin from distillation. 199248. Inst. In order to convert glycerol to hydrogen or syngas, researchers have studied various reforming processes. Methanol production uses gas-phase synthesis technology. Steam reforming (STR) is a well-established process approach that may be easily run at atmospheric pressures without the use of expensive advanced control equipment [41]. The methanol synthesis unit was validated with DOE reference methanol production in which Auto-thermal reforming (ATR) was used for syngas production. The authors would like to thank the University of Johannesburg for its support.  9b. Catalysts 9(1):15, Plcido J, Capareda S (2016) Conversion of residues and by-products from the biodiesel industry into value-added products. WebRectisol, independently developed by Linde and Lurgi, is a physical acid gas removal process using an organic solvent (typically methanol) at subzero temperatures, and characteristic of physical acid gas removal (AGR) processes, it can purify synthesis gas down to 0.1 ppm containing composition of 93.23% methanol, 6.3 % ethanol and 0.45 %. Webclockwork orange singing in the rain full scene. Asides from the impurities, the water exiting the STR section was around 55.7mol% which was condensed out of the system before introducing the gas stream into the PSA section. AIP Conf. This process takes place at higher temperatures (9001150 ) and a wide pressure range (180bar), hence a reactor that can handle these conditions is required [47]. /> [153] found that active copper species is predominantly present as Cu0 over Cu/ZrO2 based on X-ray diffraction measurements. Abstract. The generation of huge amounts of crude glycerol is one of the issues related to the usage of biodiesel. According to Ortiz et al.

9b. Catalysts 9(1):15, Plcido J, Capareda S (2016) Conversion of residues and by-products from the biodiesel industry into value-added products. WebRectisol, independently developed by Linde and Lurgi, is a physical acid gas removal process using an organic solvent (typically methanol) at subzero temperatures, and characteristic of physical acid gas removal (AGR) processes, it can purify synthesis gas down to 0.1 ppm containing composition of 93.23% methanol, 6.3 % ethanol and 0.45 %. Webclockwork orange singing in the rain full scene. Asides from the impurities, the water exiting the STR section was around 55.7mol% which was condensed out of the system before introducing the gas stream into the PSA section. AIP Conf. This process takes place at higher temperatures (9001150 ) and a wide pressure range (180bar), hence a reactor that can handle these conditions is required [47]. /> [153] found that active copper species is predominantly present as Cu0 over Cu/ZrO2 based on X-ray diffraction measurements. Abstract. The generation of huge amounts of crude glycerol is one of the issues related to the usage of biodiesel. According to Ortiz et al.

Lesson Plan About Different Body Parts And Their Movements,

313 Bus Timetable Manchester Airport To Stockport,

Articles M